RC MAKER SP1 Touring Car 1:10 - Aluminum Chassis

RCM-SP-0002

- Artnr: RCM-SP-0002

- Ej i lager

- Enhet: st

Beskrivning av artikel

RC MAKER SP1 Touring Car 1:10 - Aluminum Chassis

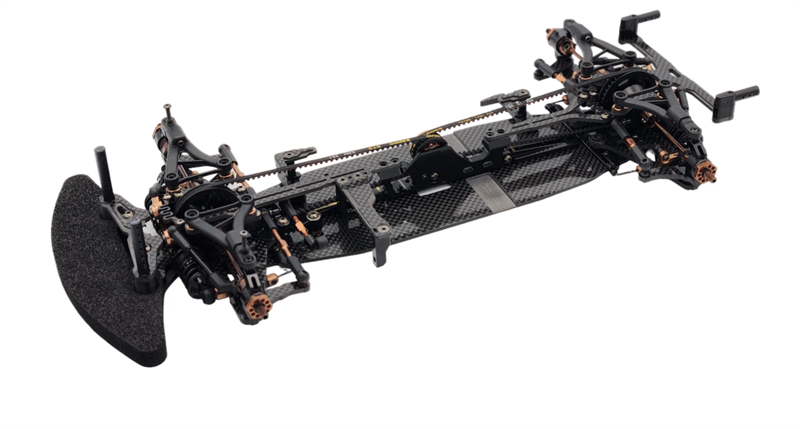

Product description RC Maker SP1 and SP1-F

RC MAKER presents the next evolution in touring car design, the SP1! A development by top touring car racer and RC MAKER owner, Ryan Maker. With over 20 years in the hobby and 8 years in the design and manufacturing industry, Ryan has always dreamed of developing his own touring car kit. What was once a pipe dream has been turned into reality over the past 2 years and thousands of hours of work. RC Maker presents the SP1, a touring car that challenges established concepts with an ultra-low center of gravity and coil-over shock design.

The SP1 is designed for everyone. A car that is easy to drive straight out of the box and has great durability. The SP1 can be customized to suit every driver's taste and track condition with its wide range of setup options and accessories.

FEATURES

- Lay-Down Push-Rod shock absorber design for ultra low CG

- 19 mm high top deck for an extremely low center of gravity

- Underarm anti-roll bar design for ultra low CG, easy changes and tweak adjustment

- Minimized chassis width and length for less ground contact

- Centrally located drivetrain and motor mount

- Centrally located suspension components to reduce the moment of inertia

- Composite upper wishbones with adjustable caster via inserts

- Aluminum differential housing for maximum heat dissipation

- Aluminum spool with the same pulley as on the rear diff

- Adjustable differential height and belt tension via composite eccentrics

- Built-in rear belt tensioner and anti-slip bearing for the center shaft (for Modified)

- Double ball bearing inner driveshaft couplings for maximum efficiency and cornering speed

- Race proven dual arm steering

- Built-in adjustable active rear axle

- Quick release battery mount with adjustment in all directions

- Hard-coated steel drivetrain for maximum durability

- All main components made of 7075 aluminum and carbon fiber for minimum weight and maximum durability

- High quality ball bearings with metal cover

- Nickel-plated screws made from high-quality steel

- Includes carbon fiber bumper mount and battery mount

- Includes 13g and 19g brass weights to stiffen the chassis

- High quality Bando 351 belts, made in Japan

- High quality shock absorber springs and bladders, manufactured by AXON Japan

INFO: NO Xray spur gears fit in the RC Maker vehicles (due to different ring gear). Axon and Arrowmax fit perfectly!

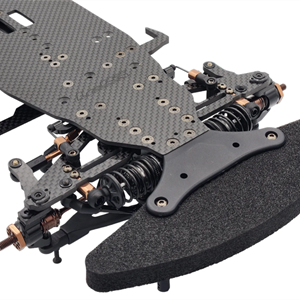

Lay down shock absorber with push rod

The disadvantage of shock absorbers has always been the high center of gravity caused by the vertical arrangement of the shock absorber. Our lay-down shock absorber takes the entire shock absorber and places it on the side of the arm, which significantly lowers the center of gravity. When the suspension compresses, the turnbuckle attached to the rocker pushes the inside of the shock outwards, providing compression. When the suspension compresses, the outer attachment point of the shock absorber is also compressed, so that the shock absorber is compressed from both sides. All aspects of this suspension geometry are highly coordinated to achieve the progressive character of a conventionally positioned shock absorber.

The damper is also adjustable outside the spring and oil. By adding or removing washers under the upper rocker arm bolt, the leverage of the wishbone movement on the strut can be changed, making the whole suspension (spring and damper) softer or harder. Of course, there is also a range of linear and progressive springs for traditional tuning.

The vehicle height is still adjusted with the cuffs and the length of the struts does not need to be adjusted as we have already set them to the optimum point. The system has been kept as simple as possible and should be as user-friendly as a conventional setup, with some additional adjustment options if desired.

19 mm high top deck for extremely low center of gravity

One of the most striking features of the SP1 is the height of the top deck. Lowering the height of the top deck dramatically lowers the center of gravity as it lowers several other aspects of the vehicle. Frames, bolts and motor mounts are lowered, which lowers the center of gravity. Lowering the top deck also makes it softer, so the thickness of the top deck has been increased to 2.25 mm to compensate for this.

Construction of the stabilizers

The stabilizers have been lowered as much as possible to lower the centre of gravity. This system also makes changing and adjusting the bars easier than ever before. The tweak is adjusted via the forearm ball cup by simply screwing or unscrewing the ball pin out of the cup (while it is attached). The open bar holder design allows for very quick changes between the 3 supplied bar strengths.

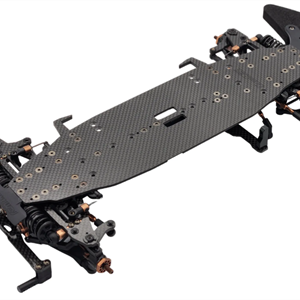

Minimized chassis width and length for less ground contact

The short chassis reduces chatter and centralizes the weight of all suspension components to reduce the moment of inertia. The wishbones are all tapered to keep the chassis short while maintaining a normal wheelbase. This moves all the bolts, ball studs and bearing shells to the center of the vehicle. This makes the car more maneuverable and enables quick changes of direction and fast cornering for maximum cornering speed. The chassis is also very narrow at just 82 mm and the profile has been minimized to reduce flutter in the corners.

Composite top link with adjustable caster via inserts

Our composite upper arms have a "fixed" caster. This option is more user-friendly and forgiving than the dual turnbuckle design found on some vehicles. The SP1 still has a wide range of caster adjustment via 2 different offset inserts that can be rotated to achieve a range of 4 degrees at each end of the vehicle. Camber can be adjusted with a special 2mm hex bolt in the arm. The front ball sockets have a built-in adjustable body stopper to prevent the body from touching and rubbing the tire.

Aluminum coil and diff

Our 7075 aluminum spool and diff offer high durability with low weight. The diff features a typical spider gear design with internal double bearings to keep the outdrives straight and low friction. The pulley is keyed into the diff to ensure minimal pressure on the bolts and housing and is kept round by the diff housing support. The spool is characterized by a typical lightweight design with wedged screw drives. Similar to the diff, the pulley is also wedged into the spool to relieve the screws from the drive and braking force. Both the spool and the diff drives are made of hard-coated steel to minimize wear.

Adjustable diff height and belt tension

Our composite eccentrics are available in 2 diff heights and 7 belt tension positions. The eccentrics can be easily rotated when the upper bulkheads are released and re-engaged. They sit slightly loose in the bulkheads to ensure the vehicle can move in these areas under load.

Built-in rear belt tensioner and anti-slip bearing for the center countershaft

The SP1 has an adjustable rear belt tensioner as well as a center anti-slip tensioner used for Modified racing only. The center tensioner is adjustable in strength and prevents the belts from slipping on the center pulley under heavy Modified racing loads. These tensioners increase friction, which is why we recommend using them for Modified racing only.

Drive shafts

All major components of the driveshafts are hard coated to ensure maximum longevity. The driveshafts themselves have a traditional design that is manufactured to a high tolerance. The inner driveshaft couplings minimize friction and wear on your driveline. They prevent the suspension from locking under load, allowing the suspension to work freely when accelerating, braking or cornering. The bearings also minimize wear on the differential and spool drives, so your entire drivetrain lasts longer. They may be a pain to install, but they are absolutely a performance-enhancing component of the vehicle.

Shock absorbers and springs

The SP1 shock absorbers are made from high-quality, low-friction components. The damper body is coated with a diamond-like coating that reduces friction and minimizes wear. This is crucial for ensuring that the shock absorber works as smoothly and quietly as possible, even under the heaviest loads. The dampers feature a modern design with a bladder integrated into the damper body for easy, air-free installation. The ladder itself is made of a soft material and is manufactured by AXON in Japan. The SP1 has a full range of optional linear and progressive springs, also manufactured by AXON in Japan.

Battery holder with quick release

The installation of the battery is an important part of the vehicle as it is such a heavy component. The SP1 has easily twistable tabs for quick battery replacement. The kit includes carbon battery hooks that slide in and out for different battery widths. The forward/backward movement of the battery can also be adjusted by the eccentric battery posts. Simply loosen and rotate the post at different points to adjust the position or movement of the battery.

Brass weights

The positioning of the weights is very important on mid-engine chassis. The SP1 contains centrally mounted front and rear weights that are positioned in front of and behind the motor mount. These are made of brass and coated in black. They are included in the kit as they are crucial to bringing the car up to weight, and also essential for tuning the flex of the car.

High quality hardware

The SP1 is fitted with premium quality screws and bearings throughout. The bolts are nick-coated, which not only looks good, but also provides a tough and corrosion-resistant (rust-proof) coating, which is especially important for drivers in humid areas. All washers are 6061 aluminum with a black anodized finish.

Manufacturing

The SP1 has a range of components manufactured in Australia by RC MAKER as well as in Taiwan and China. All parts are manufactured to the highest tolerances and tested before packaging.

Support

As with all RC MAKER products, the SP1 is backed by a large support network. When the SP1 is out on the race tracks around the globe, there will be a public collaboration between RC MAKER, customers and team drivers. This will ensure help with set-up, assembly or any problems that may arise. RC MAKER is committed to providing the best support for your SP1, no matter where you are in the world.